Paper

Operation technology of industrial silicon smelting with all coal and calculation of parameters of submerged arc furnace

Updated: 2022-04-28 Attention:

Combined with the process requirements of industrial silicon production from whole coal, reasonable geometric and electrical parameters are selected in order to design or transform industrial silicon electric furnace, create conditions to meet the requirements of whole coal smelting and ensure normal production.

The geometric parameters of electric furnace include electrode diameter, pole center circle diameter, furnace diameter and furnace depth. The electrical parameters include many variables such as molten pool resistance, electrode current and working voltage. It is necessary to select a reasonable operating resistance according to the nature of bituminous coal in order to control the current voltage ratio under the appropriate secondary voltage gear.

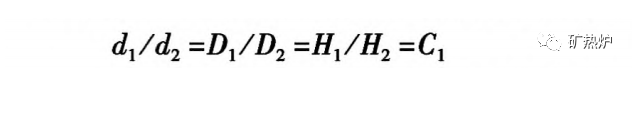

Geometric parameters such as polar circle diameter "d", furnace diameter "d" and furnace depth "H" of submerged arc furnace are usually calculated by similarity:

Where, the lower corner marks 1 and 2 respectively represent electric furnaces with the same variety and different capacity.

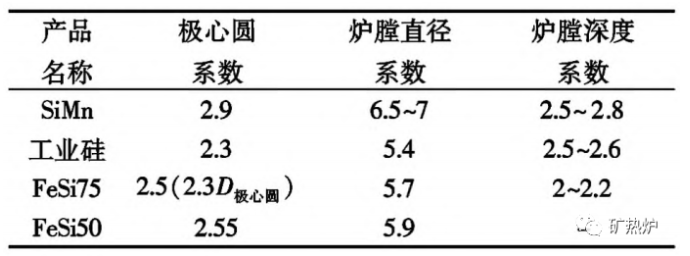

The geometric parameters of submerged arc furnace, such as polar circle diameter, furnace diameter and furnace depth, are usually designed according to the multiple of electrode diameter. The following table lists these empirical coefficients.

Multiple relationship between geometric parameters of electric furnace and electrode diameter

1. Electrode diameter (d)

There are professional standards for graphite electrode, but there is no national standard or industrial standard for carbon electrode at present. Manufacturers still regard it as "non-standard production" according to the needs of users, so there are great differences in physical and chemical indexes. The recommended current density is 5 ~ 10A / cm ² Carbon electrode, but from the actual use of enterprises, it is 6 ~ 7a / cm ² Most of the carbon electrodes are economic current density ports.

The electrode diameter of industrial silicon electric furnace can also be calculated by the following formula:

In the above formula, D electrode - electrode diameter, P A - active power, kW; K ₁ - coefficient, taken as 1.4.

2. Polar circle

The concept of electrode center circle is related to the power density of the reaction zone and also has a certain influence on the working voltage of the electric furnace.

The polar circle diameter () is an equipment structural parameter that has a great impact on the smelting process. The polar circle diameter of the electrode is properly selected (Fig. 1-1). The action area of the three electrode arcs intersects the furnace core (the diameter of the electrode reaction zone is equal to the polar circle diameter of the electric furnace). The electrode reaction zones are connected and the overlapping part is the smallest. In this case, the heat distribution in the furnace is reasonable, the crucible molten pool is the largest, the feeding is uniform, and the furnace condition is stable, The furnace condition is also easy to adjust. If the pole center circle is too small (Fig. 1 ・ 2), the distance between electrodes is too small, the charge resistance decreases, the charge current increases, and the electrode is not easy to be deeply inserted; The pole center circle is too large (Fig. 1 ・ 3), and the crucibles under the three electrodes are not easy to connect, forming three separate small molten pools. The insufficient heat in the furnace core is not conducive to the full reduction of SiO ν. The slow melting of the furnace core or the insufficient reduction of the silica in the furnace core will sink into the furnace bottom and increase the slag accumulation in the furnace, which will also lift the electrode and affect the furnace condition.

Figure 1 polar circle diameter

The method of geometric ratio is often used to determine the electrode diameter, that is, the electrode diameter is multiplied by the electrode concentric circle coefficient. Because the current density range when calculating the electrode diameter is very large, and the electrode diameter of the furnace with the same capacity is also very different, so the determination of the diameter of the pole center circle is mainly considered from the perspective of electricity and energy: ① the optimal power density of the pole center circle. If the power density is large, the temperature of the molten pool will be high and the molten pool will be large. The optimal power density should be that the three-phase molten pool intersects properly, that is, the circumference of the three molten pools intersects the center of the furnace without dead angle, Without excessive concentration; ② The potential gradient between electrodes, that is, the ratio of the voltage between electrodes to the distance between electrodes, reflects the charge resistance and current between electrodes.

The potential gradient between silicon electrodes in the whole coal smelting industry is selected as about 0.145v/mm, and the average power density of the pole center circle is 2250-3000kw / m ²。

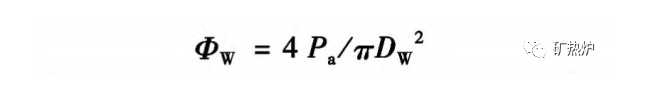

The diameter of the polar circle is calculated by the power density relationship per unit area of the polar circle. The following formula:

In formula (6) Φ W - polar circle power density, kW / M ²; Pa - active power, kW; DW - diameter of polar circle, M.

3. Furnace diameter

According to the theory of reaction zone, the diameter of electrode center circle of electric furnace is the same as that of each electrode reaction zone; The reaction zone of electric furnace is twice the diameter of electrode. As the outlet is the weakest part of the furnace lining, it is easiest to burn through, and the furnace diameter is usually slightly larger than required. Experience shows that the furnace diameter should be greater than twice the polar circle diameter DW, so that the smelting area does not contact the furnace lining. The author suggests that d = 2.3d electrode.

The commonly used calculation formula is: D furnace = 2dw + D electrode

4. Furnace depth

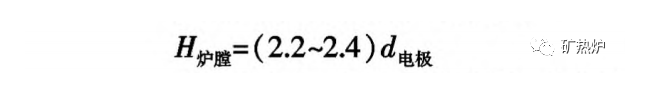

The furnace depth is generally calculated by empirical method, that is, the furnace depth is calculated according to the multiple of electrode diameter.

The furnace depth should be appropriate and deeper, which is conducive to the operation of flat top material surface, reduce the furnace mouth temperature, improve the working environment at the production site, reduce the volatilization loss of SiO2, concentrate heat in the furnace and reduce heat loss. The furnace is too deep, and the operation is slightly careless, that is, the material layer is too thick, the material level rises, and the high-temperature area in the furnace moves upward, which eventually leads to the rise of the electrode, the decrease of the furnace bottom temperature, and the deterioration of the furnace condition. If the furnace is too shallow, the material layer will become thinner, the volatilization loss of Si (2) will increase, which will affect the reduction of Si, reduce the output and increase the energy consumption, especially increase the heat loss at the furnace mouth, the temperature at the furnace mouth is too high, and the production labor environment will become significantly worse, which is easy to produce material collapse and fire, so that the smelting process can not be carried out smoothly.

The working depth of furnace is calculated according to the following formula:

In the above formula, the large electric furnace takes the large value and the small electric furnace takes the small value.

The average power density of silicon furnace in all coal smelting industry is 200kW / m ² There is no corresponding relationship with the capacity of the electric furnace.

(1) For industrial silicon smelting with all coal, the specific resistance of furnace charge increases and the furnace condition operates stably, which is shown as follows:

① The charcoal as an adjustable part in the proportioning ratio shall be cancelled, and the operator in front of the furnace shall master the accurate proportioning ratio. At the same time, due to the stable burden ratio, the phenomena of "heavy burden" and "light burden" are avoided.

② The electrode is buried deeply, the phenomenon of "pricking fire" and "material collapse" on the material surface is less, the heat in the furnace is concentrated, and there is only a small amount of small caking on the material surface. The operation in front of the furnace is easy, the labor intensity is reduced, and the tamping cycle is prolonged by about 15min.

③ When smelting industrial silicon with all coal, there is a large flow when discharging, accompanied by a small amount of viscous slag, which is caused by the increase of furnace temperature and the expansion of crucible. At this time, the tapping and burning time is slightly prolonged, but the extension of refining time by about twice does not affect the product quality.

④ Due to the use of high voltage, a large amount of silicon liquid accumulates in the silicon liquid area in the furnace before discharging, which makes the electrode lift up and the current fluctuate greatly. Therefore, the current should be reduced appropriately to keep the furnace stable.

(2) Strengthen the material level operation and reduce the volatilization loss of SiO.

The volatilization loss of SiO will cause: ① the reaction balance between C and SiO ν is destroyed and the reduction ratio is out of balance; ② With the change of time, the loss of SiO will lead to the fluctuation of furnace condition, and the furnace condition needs to be adjusted frequently; ③ Rich and refractory SiC Based aggregates are produced in the furnace, causing the electrode to rise and the furnace bottom to rise.

(3) When bituminous coal is used, the furnace charge settles slowly, which is conducive to the full discharge of moisture and volatile components in the reducing agent at the furnace mouth. The amount of labor for treating the furnace mouth can also be reduced by 20% ~ 30%, and the permeability of the furnace charge is improved. The temperature of molten silicon rises and the furnace condition is relatively stable. However, due to the high volatile content of bituminous coal, high charge surface temperature and more burning loss of reducing agent, the furnace door cannot be completely closed, and a gap of about 200mm is reserved at the bottom to control the charge surface temperature and improve the recovery rate of silicon.

(4) Surface sintering of charge is a special furnace condition characteristic in industrial silicon smelting. The sintering of charge is mainly caused by the disproportionation reaction of SiO gas. On the one hand, the condensation reaction of SiO generates SiO ν and Si, which closes the escape path of furnace gas; On the other hand, the condensation reaction of SiO and the oxidation of silicon release a lot of heat energy, which makes the silica soft melt.

Once a small amount of high-pressure gas is ejected from the surface of the crucible, it can only form a gap along the surface of the crucible. The electric furnace stabbing fire causes a large amount of heat energy to be carried into the flue gas by the escaping SiO gas. Frequent ignition will reduce the recovery rate of silicon and increase the power consumption.

Improving raw material conditions and furnace mouth operation are necessary measures to improve charge permeability.

Since all reducing agents are smelted with bituminous coal, their air permeability is not as good as charcoal, so a wood block of burden loosening agent must be reasonably selected. With more use of loosening agent, the volume of furnace charge increases, which is easy to collapse and prick fire, and is more wasteful; Less consumption and poor air permeability of charge make smelting difficult. At the same time, due to the large amount of impurities and slag in bituminous coal ash, attention must be paid to slag discharge at any time, otherwise it will cause excessive slag accumulation at the bottom of the furnace, increase the furnace temperature and make it difficult to discharge.

(5) Loosening the charge structure of sintering by ramming furnace is an important operation of industrial silicon smelting. The main purpose of furnace tamping operation shall be to loosen the furnace charge and improve the air permeability. Improper tamping operation will damage the structure of the crucible reaction zone or increase the heat loss at the furnace mouth.

Whatsapp

Whatsapp